When it comes to attaching solar modules to metal rooftops, traditional rails have been a conventional choice. But familiar concepts don’t necessarily deliver the best outcomes, and the advantages of rail-less solutions are moving the industry in a new direction.

Decades ago – when interest in mounting solar PV on rooftops began – the introduction of using continuous aluminum rails as a solar racking system to mount PV modules in place was a practical application for all roof types. Eventually, innovation opened new doors and rail-less solutions were developed specifically for metal roofing. Using discrete hardware to directly secure each module to a metal roof, the new strategy completely bypassed the need for rails and brought some clear improvements.

Today, we’re breaking down the top rail-less benefits leading to a growth in popularity and positioning rail-less to be the new metal rooftop solar mounting standard for the future.

1

Reduce Materials’ Cost and Lighten the Load on Your Roof

Resourceful by their very nature, rail-less solutions leverage your roof’s existing construction to protect your roof and your wallet.

|

|

The seams of a standing seam metal roof and the ribs of an exposed-fastened metal roof can be used as the points of attachment for solar panels - without the need to install the additional load of rails.

- You have inherent rails already on your metal roof – in the form of seams on a standing seam roof and trapezoidal ribs or corrugations on an exposed-fastened roof. Using these basic metal-roof components as the rails for solar mounting saves you unnecessary redundancy and cost in hard goods.

- Rail-less products are much lighter than railed systems, which reduces loads to the building structure. In fact, properly engineered rail-less components weigh 85 percent less than most railed systems.

- Because every point of attachment touches your roof, rail-less offers a 25 percent better load distribution across the roof.

2

Sidestep the Logistical Nightmare

Wouldn’t it be great to remove the logistical headaches and inconvenience common to traditional railed systems? With rail-less solutions, you can. Rail-less makes shipping, storage and transport simple and much less expensive.

You save money on logistics with a rail-less solar PV mounting solution.

- Shipping - Rail-less attachments are 15 percent of the weight of solar racking systems. A 50-kilowatt (kW) system using rail-less components weighs only 150 pounds and ships in three boxes by FedEx or UPS – a far cry from the need for the flat-bed shipping of long aluminum rails. You save more than 60 percent in shipping costs.

Rail-less attachments are 15 percent of the weight of solar racking systems. A 50-kilowatt (kW) system using rail-less components weighs only 150 pounds and ships in three boxes by FedEx or UPS – a far cry from the need for the flat-bed shipping of long aluminum rails. You save more than 60 percent in shipping costs.

Rail-less attachments are 15 percent of the weight of solar racking systems. A 50-kilowatt (kW) system using rail-less components weighs only 150 pounds and ships in three boxes by FedEx or UPS – a far cry from the need for the flat-bed shipping of long aluminum rails. You save more than 60 percent in shipping costs.

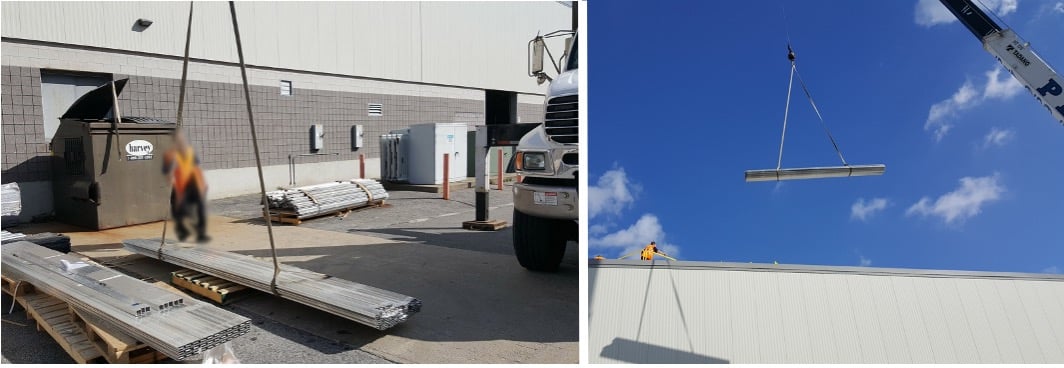

- Storage and Handling - Offering a 90 percent savings in physical volume warehouse space, no large off-site (or on-site) storage area is ever needed with rail-less, so you can often avoid cumbersome cranes and forklifts.

You can save money in logistics with a rail-less solar PV mounting solution.

- Transport to the Job - The mobility of rail-less is surprising. The components for a 500kW PV system weigh 1,500 pounds and easily fit in the back of your short-bed pickup truck. A 150kW rail-less mounting system stows in the trunk of your car, and the components for a 50kW system will tuck into the front seat of your MINI Cooper.

Image on the left shows the equivalent mounting hardware required when using a rail-less solution versus a rail-based system.

3

Install With Ease

Rail-less solutions have transformed the installation process. Once you understand the basics of rail-less mounting, installation is a snap.

- Rail-less solutions let you easily mount around obstacles, removing the awkward field-cutting of rails. Plus, “on-the-fly” changes in the install area are possible if you need to make them.

- With 70 percent fewer components than traditional systems, rail-less solutions make it simple and quick to get all the components up on the roof and into place. You can carry a 12kW complete mounting system up the ladder in a backpack or a 36-pound bucket.

- It’s easy to move components around during your install, which is especially beneficial when you’re working on a steep slope.

Example installation of a rail-less solar PV system on a steep-slope metal roof.

- In most cases, you only need one tool for the full install.

Installing a rail-less solar PV mounting system with a screw gun on a standing seam metal roof. (Product shown: S-5! PVKIT® 2.0)

- State-of-the-art rail-less solutions also give you tie-slots and other tricks for wire management to help organize this critical part of your system’s performance.

- With railed systems, of course, modules are installed 90º to the rail resulting in portrait orientation to the roof. With rail-less systems, you still install 90º to the rails (ribs or seams), but now the modules are in landscape orientation to the roof. And the “rails” are abundant, so you have greater flexibility available to you—AND best of all, they are free!

4

Spend Less Time on the Roof

The faster you can successfully complete an install, the more customers you’ll be able to serve. Rail-less speeds installation thanks to its streamlined system and smooth process.

- Rail-less solutions are pre-assembled, so you have less parts to manage.

- Rail-less is designed so the clamps can be quickly aligned and modules installed “on-the-fly,” using your first module as a guide for the next one’s placement.

- Installers report installation times of less than 90 seconds per module.

- You’ll save an average of 35 percent or more on labor.

5

Preserve Your Investment

The value of metal roofs lies in their durability – they can last for more than 60 years – and their beauty. Any roofing attachment needs to ensure these qualities remain intact.

- The low-profile of rail-less systems helps prevent animals and debris from collecting under the PV modules, safeguarding the solar array’s performance and your roof.

- Sporting a low-profile also gives rail-less solutions a sleeker visual appeal, so your roof maintains better aesthetics.

- And when you pair a rail-less solution like the direct-attach PVKIT with a non-penetrating S-5! clamp on a standing seam roof, you get the added benefit of a penetration-free mounting system designed to protect your roof’s warranty and integrity.

Ideas to Hold Onto

Rail-less is beginning to move forward in the field of metal rooftop solar mounting. It takes time for any industry to adopt newer practices, but the advantages of rail-less mounting are becoming increasingly well known. Let’s recap the five main reasons rail-less is gaining ground:

- You place less load on the roof and gain cost savings on materials.

- You can say goodbye to complicated and high-priced logistics.

- Installation is straightforward and offers you more flexibility.

- Faster installs give you more time to help customers.

- You can help safeguard the investments you made – both in your solar PV and your roof.

As more installers and contractors experience the benefits of rail-less solar mounting firsthand, this innovation is destined to be the go-to solution in the future.