Micro rails are a relatively common way of attaching a solar array to exposed-fastened metal roofs. This method uses small rail sections in specific areas as needed along the roof – reducing the total length of rails. They have benefits which make them desirable to contractors and installers alike. They provide material and shipping cost savings to the customer when compared to rail systems. In addition, they are small, which allows them to be handled easily onto roofs. They are forgiving with spacing allowing for minimal or customizable walk spaces. Additionally, micro rails can be installed with just a couple of fasteners - potentially cutting installation times compared to rails.

BUT…

Mounting Solar With Micro Rails: A Good Idea?

The benefits of micro rails seem not to outweigh any potential cons. The problems with micro rails can be seen once you dig more into how these rails are actually installed. The issue stems from the way micro rails are attached to the sheet metal on the roof and the way uplift loads are distributed into the fasteners. We look at two main concerns with micro rails: both concerning uplift loads.

First Concern: Direct Pull-Out vs Shear Load

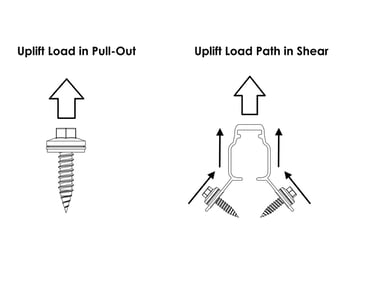

A major issue is the way micro rails are fastened straight into the top of the roof ribs. Due to this fastening method, the uplift loads that the solar panels produce result in the fasteners experiencing direct pull-out load. Vendors explain that although the tested pull-out value of the fastener is quite low, it is doubled in calculation because there are two fasteners. This is an erroneous assumption for reasons explained here.

|

| Figure 1 |

In the thin gauges of sheet metal from which exposed-fastened roofs are made, the pull-out strength of fasteners is considerably less than shear strength (See fig 1). Shear strength can be utilized only with special bracket designs that convert direct force into shear force instead.

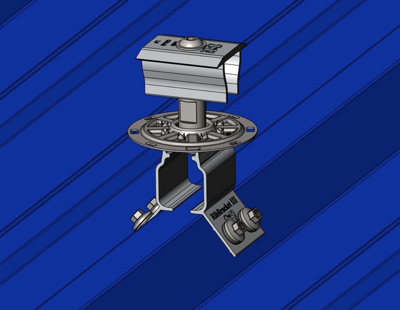

Figure 2 shows S-5!’s RibBracket I-IV™ (RibBracket III is featured in the graphic) with a PVKIT® 2.0 MidGrab. This kind of bracket has four fasteners that are in shear and features high-quality factory-applied EPDM for waterproofing. These brackets can be placed anywhere along the rib making them very convenient for rail-less solar installations as the bracket does not need to tie into the structure below the roof.

|

| Figure 2 - S-5!’s RibBracket III with a PVKIT™ 2.0 MidGrab |

Second Concern: Non-Concentric Load

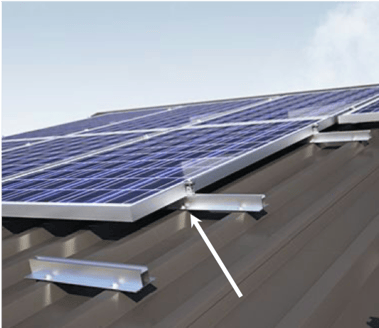

Although the micro rail attaches with two fasteners, the point of load is never concentric to them. The grab of the micro rail is never at perfect center on the rail, so the uplift load that is going through the grab is not evenly distributed between the fasteners. This is shown in fig 3 where the entire load is experienced by a single fastener.

When uplift loads are significant, reliance on the full published pull-out strength of the fasteners will likely result in disaster. Making matters even more uncertain, often the vendor publishes only the “ultimate” pull-out value with no factor of safety. The solution to such problems is one of the two below:

|

| Figure 3 – Micro Rails (Source: Indiamart.com) |

- Double the quantity of micro rails, and add a factor of safety; however, this will also double the cost—or more.

- Use a bracket that can mount the grab over a single rib, fastening into the sides, so that the fasteners are in shear—not direct pull-out, and rely on tested (rather than mis-calculated) holding strength and with factors of safety applied. The bracket in figure 2 demonstrates an example of this.

In conclusion, micro rails have their upsides, but the downsides need to be considered when designing an exposed-fastened rooftop solar array. Pull-out and uplift loads with micro rails are unpredictable and may result in a reduction in holding capacity.

Numerous other metal roof mounting products are available on the market at a similar price point (when you do the math) and are made specifically to do what micro rails do― all without the downsides. All things considered; micro rails may fall short of the competition in the majority of situations.

Solar Mounting Solutions

S-5! offers both rail and rail-less solar mounting solutions for exposed-fastened metal roofs. Explore our line of brackets for rack and rail systems. Thinking of going rail-less? Our PVKIT 2.0 is the the best solution for attaching PV modules directly to any exposed-fastener metal roof.