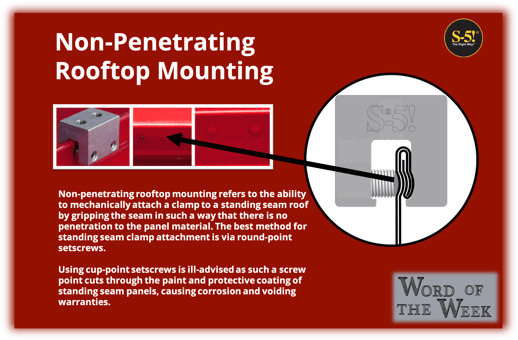

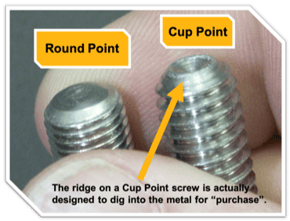

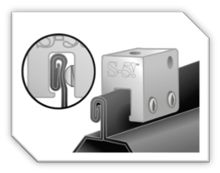

Non-penetrating rooftop mounting refers to the ability to mechanically attach a clamp to a standing seam roof by gripping the seam in such a way that there is no penetration to the panel material. The best method for standing seam clamp attachment is via round-point setscrews.

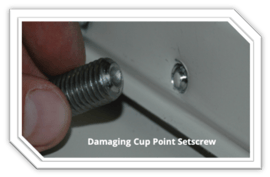

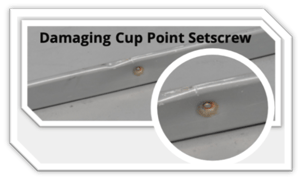

Using cup-point setscrews is ill-advised as such a screw point cuts through the paint and protective coating of standing seam panels, causing corrosion and voiding warranties.

In the metal roofing construction industry, mounting ancillary items is often a convenient and necessary aspect of desired performance. Obviously, the best way to maintain the integrity of a metal roof is to allow it to function only as a roof. But various rooftop utilities such as, HVAC, piping, walkways, vents, satellite dishes, snow retention, solar arrays, signage, fall protection, lightning protection, etc. all serve critical purposes and must attach to the roof.

The first

The first rule of thumb in rooftop mounting to modern standing seam roofing is to do the roof no harm – so foremost, that means don’t penetrate it. But when it comes to standing seam metal roofs, mounting rooftop equipment can often result in violated warranties and roof damage if not done correctly. Often, the tendency of trades is to anchor the item to the structure through the roof. But doing so threatens weather integrity and also violates the membrane’s thermal-cycling behavior by pinning the panel to the structure. The point of attachment will soon fatigue and fail due to thermal expansion. But the right non-penetrating mounting solution provides secure attachment without any penetration whatsoever—and without violating freedom of thermal cycling.

rule of thumb in rooftop mounting to modern standing seam roofing is to do the roof no harm – so foremost, that means don’t penetrate it. But when it comes to standing seam metal roofs, mounting rooftop equipment can often result in violated warranties and roof damage if not done correctly. Often, the tendency of trades is to anchor the item to the structure through the roof. But doing so threatens weather integrity and also violates the membrane’s thermal-cycling behavior by pinning the panel to the structure. The point of attachment will soon fatigue and fail due to thermal expansion. But the right non-penetrating mounting solution provides secure attachment without any penetration whatsoever—and without violating freedom of thermal cycling.

|

|

Word De-Construction

Word of the Week: Non-Penetrating Roof Top Mounting

PRONUNCIATION: /nän/ | \ ˈpe-nə-ˌtrāt

PART OF SPEECH: Prefix, Adjective

SENTENCE: // There are two basic methods available for mechanical attachment of things like snow retention systems to roofs: One uses the process of clamping to the seam (non-penetrating); the other screwing through the roof material (penetrating).

SYNONYMS AND RELATED WORDS: dimple, no rooftop damage, maintain roof warranty, mechanical compression

THE SCIENCE BEHIND NON-PENETRATING ROOFTOP MOUNTING SOLUTIONS: Mounting ancillary items to standing seam metal roofs requires secure and dependable attachment but need not cause puncturing. Metal’s malleability (ability to be drawn out or stretched) qualities make it a prime candidate for seam clamps. Using seam clamps eliminates unwanted holes in the roof and maintains the warranty.

The clamps themselves should be made of non-corrosive metals (e.g. aluminum with stainless-steel mounting hardware). Aluminum and stainless-steel offer the most compatibility with all metals except copper. If copper roofing is involved, use brass clamps and stainless-steel to help alleviate metallurgy issues.

Metal roofing seam clamps efficiently integrate with standing seam profiles and pinch the seam material to anchor them in place. This anchoring utilizes setscrews that dimple or indent the material as they are tightened. The key aspect of this process is the mechanical interlock it creates between the setscrew, the seam, and the clamp. A properly engineered and tested seam clamp provides the greatest holding strength and durability. Always use clamps that have been load-tested for the specific material and seam-specific holding strength in question. The in-service load should not exceed the published holding strength.

Metal roofing seam clamps efficiently integrate with standing seam profiles and pinch the seam material to anchor them in place. This anchoring utilizes setscrews that dimple or indent the material as they are tightened. The key aspect of this process is the mechanical interlock it creates between the setscrew, the seam, and the clamp. A properly engineered and tested seam clamp provides the greatest holding strength and durability. Always use clamps that have been load-tested for the specific material and seam-specific holding strength in question. The in-service load should not exceed the published holding strength.

S-5! Non-Penetrating SSR Clamps

https://www.s-5.com/products/clamps-brackets/clamps/

Why S-5! Clamps are The Right Way to Mount Almost Anything to a Standing Seam Roof:

Metal Roofing from (A) Aluminum to (Z) Zinc – MCA

Solar Solutions for Standing Seam Metal Roofs

Standing Seam vs Exposed Fastener Metal Roofs