This is Part Two of a two-part series on qualifying snow retention systems.

In Part 1 of What’s on Your Roof? we discussed how, unfortunately, there aren’t any snow guard police out there patrolling the industry. This creates a two-fold problem: One, that you can’t count on there being building inspectors to check a go-to-market system for structural adequacy; and two, architects and installers of these systems can potentially be sued for personal and property damage from faulty snow retention systems they specify or install.

But the light at the end of the tunnel comes in the form of the recently published Qualifying Snow Retention Systems by the MCA (Metal Construction Association). This technical guide bridges the gap between the free-for-all snow guard market and building owners, installers, and architects, who demand knowledge, strength, and a well-engineered system. So, what exactly constitutes a well-engineered system?

Predictability and Control are the Name of the Game

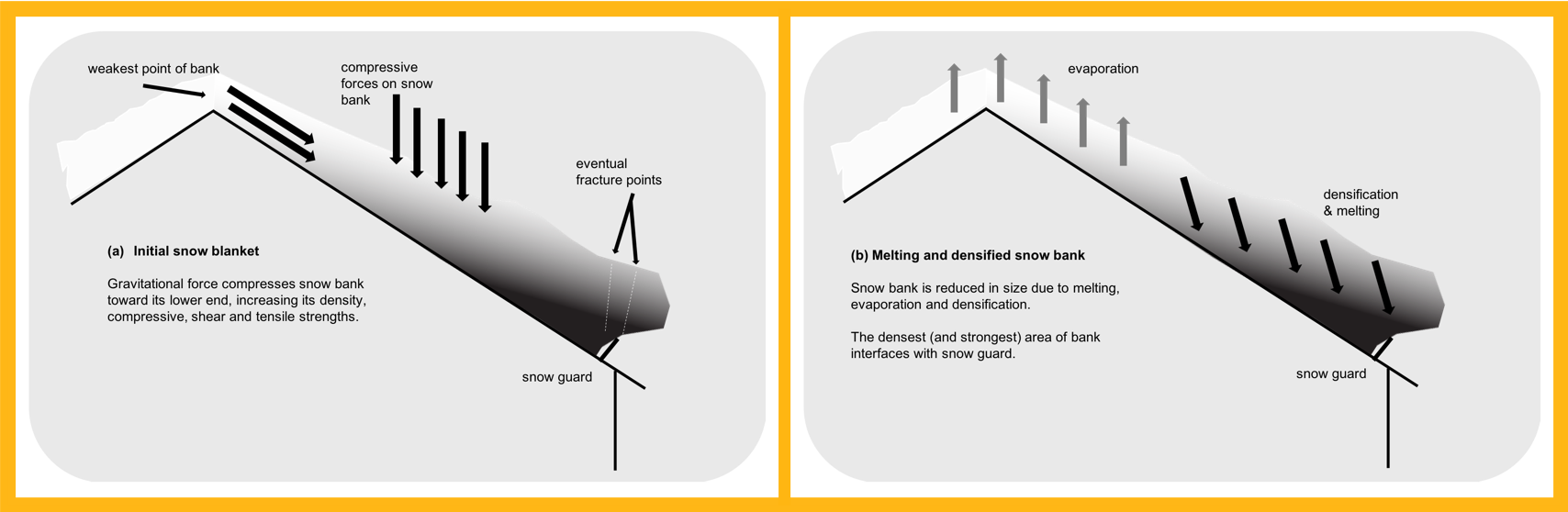

Recall from Part One, that a snow guard immobilizes the snow on the roof at its densest point. It increases friction between the roof and snow, which retains snow pack on the roof, so that it evacuates in a predictable and controlled fashion (through thaw and evaporation) rather than by a sudden and dangerous rooftop avalanche. Snow guards rely on the compressive strength of the mass of snow in order to restrain the snow’s movement. Gravitational forces compress the snow bank immediately adjacent to the roof surface and especially toward its lower end, increasing its density, and therefore its compressive strength.

Engineer Your Snow Guard System to Last

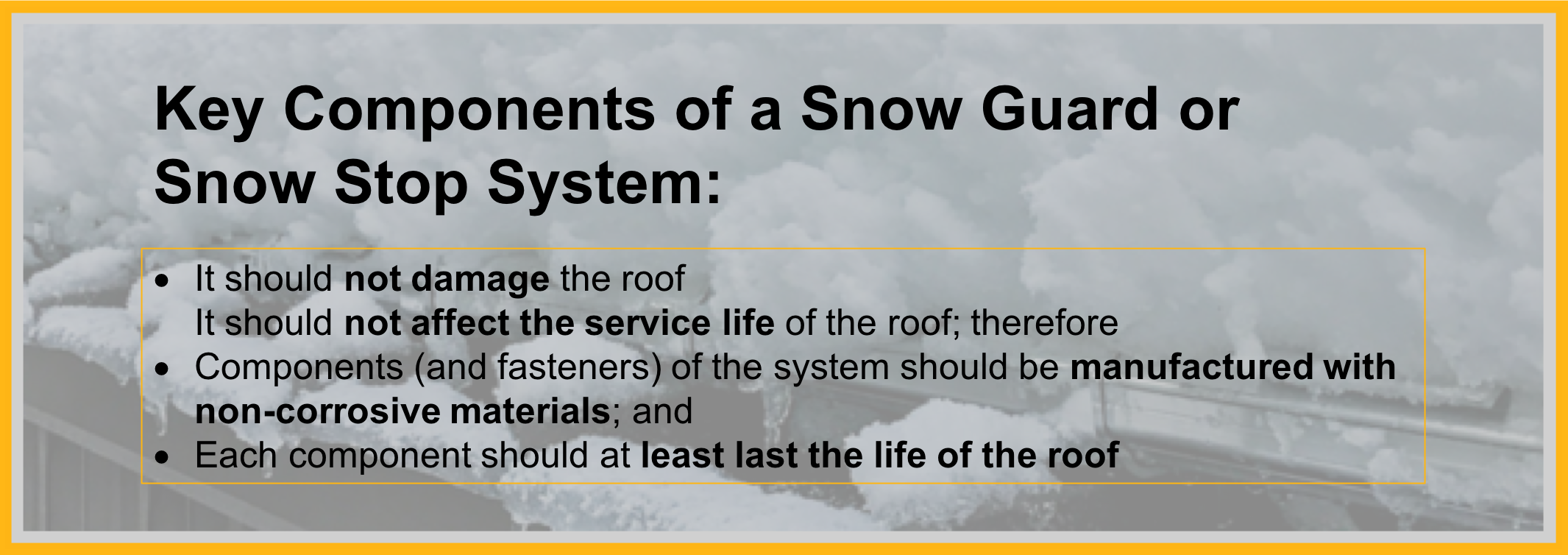

With all that being said, to be effective, a snow retention system must integrate with (but doesn’t necessarily have to penetrate) the roof. Technical jargon aside, basic engineering principles must be followed with any quality snow retention system. This begins with extensive load testing.

Durability and Reliability

The Clamp Bone’s Connected to the Panel Bone

A snow guard system often has a beam-like cross-member, which “spans from clamp-to-clamp (or bracket to bracket) and is designed to restrain the snowpack and transfer the force of sliding snow into the clamp and/or bracket.” Structural components (e.g. mechanically fastened unitized snow-guards, seam clamps anchored to the roof seam, cross-members, or brackets that support cross-members) anchor the system and transfer “the vector load of the snowpack to the structure, roof covering, or another primary component.” Let’s further define these structural components.

|

Seam Clamp: Also known as a standing seam roof clamp, is a non-penetrating element that pinches the seam using rounded point set screws tensioned against the seam material. “The seam clamp transfers load from the continuous snow-guard into the panel seams.” |

|

Snow Clip/Ice Flag/Snow Flag/Splices: Clips are minor components, but they do enhance the performance of the primary components listed above. Their purpose is to “restrain snow and/or ice from sliding beneath the cross-member.” |

|

Cross-Member Splices: Purpose is described above, but specifically, these splice or join sections of cross-members to “maintain alignment and/or structural continuity.” A splice is used to expand your system across the roof. |

So Really, How Important is Snow Guard Placement?

To the casual observer, snow guard placement on the roof may not initially appear to be very scientific. One might even suggest that the more random the placement, the better the chance for holding snow. This is not necessarily true – and can actually be quite a dangerous suggestion.

Snow densification is a science unto itself and requires a series of calculations to aid in guard placement. Metal Roof Design for Cold Climates is an excellent resource and reference guide. But generally, “the entire eave line of a building should be protected, rather than focusing on an isolated area of the roof.” It is difficult to determine exactly how snow will react on a short section of snow guards on a very large roof. Additionally, it is unwise to only position snow guards above doorways. You might not be walking under a particular roof section, but you create unstable, unpredictable, and uneven load balances on the roof panels and snow guards.

As unpredictable as snow may appear to be, these tested and trusted guidelines are successful in facilitating safe snow guard system design. Generally stand-alone and unobstructed sloped metal roofs, more often than not, force snow “to accumulate, densify, and migrate…with somewhat greater concentration near the eaves.” But different designs dictate different needs. MCA (and S-5!) always recommend that snow guards and snow retention systems be installed on a job-specific basis after determining the best design for the project.

“Buyer-Beware” No More

No industry standard exists for the process of designing and testing snow retention systems. This speaks to the critical nature of the educated consumer as well as the conscientious vendor. But with lives and property at stake, there is no excuse for installing a faulty snow retention system. Qualifying Snow Retention Systems for Metal Roofing is your go-to-source for engineering-based, vetted, technical data that will assist in qualifying and selecting snow retention products and sources that perform consistently for the protection you need.

S-5! takes product and design seriously by offering online tools that follow MCA’s guidelines for every single one of our snow retention systems. Explore our entire line of snow stops and snow retention solutions. Whether color-matching, architectural design, extra strength, or a smooth brass finish is your primary purpose, all of our products are tested, trusted, and engineered to dramatically reduce the risks associated with rooftop avalanches while maintaining the clean lines of the roof. Have more questions? Explore our comprehensive list of FAQs.

For additional trusted and technical information and advice, check out MCA’s (Metal Construction Association) vast library of free downloadable documents.

Remember - Snow Retention isn’t voodoo. It isn’t guesswork either — it’s proven science!

Revisit Part 1 in our series on qualifying snow retention systems.

...to the S-5! Blog!