A corrugated panel has a repeating wavy or rippled pattern across its design. It was the first mass-produced metal panel design in the United States. These panels can be used for roofing, siding, decking, and flooring. Corrugated panels are connected by overlapping the sheets, and then securing them in place with exposed fasteners. Trapezoidal rib panels are often mistakenly referred to as corrugated roofing.

Word De-Construction

Word of the Week: Corrugated

PRONUNCIATION: \ ˈkȯr-ə-ˌgā-təd

PART OF SPEECH: Adjective

SENTENCE: // The CorruBracket™ 500T from S-5!® is specifically designed to prevent penetration and subsequent leaks from occurring in the profile valley.

// The pattern on a corrugated metal roofing panel is similar to a sinusoidal wave.

SYNONYMS AND RELATED WORDS: wavy, wrinkled, rippled, sinusoidal wave

WHAT PRODUCTS DOES S-5! OFFER FOR CORRUGATED ROOFING PANELS?: S-5! offers three metal roof brackets to facilitate attachment of almost anything to a corrugated metal roof.

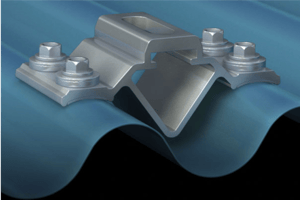

CorruBracket™

The CorruBracket can be used to mount almost anything to corrugated metal roofing and is compatible with 7/8″ and 3/4″ corrugated roofing. This roof bracket requires no messy sealant during installation. It comes with factory-applied butyl sealant already in the base, and the reservoir conceals the sealant, preventing UV degradation.

LEARN MORE ABOUT CORRUBRACKET™

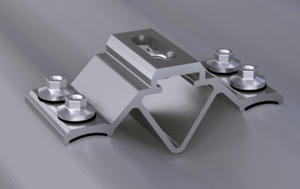

CorruBracket™ 100T

CorruBracket 100T is the perfect choice for the common corrugated metal roof profiles in North America.  Use this bracket for solar panel mounting via rail or with DirectAttached™ methods.

Use this bracket for solar panel mounting via rail or with DirectAttached™ methods.

CorruBracket 100T is affixed to the crest of the corrugation, leaving the drainage plane free of holes to protect against leaks. CorruBracket 100T already comes with a factory-applied rubber gasket seal on the base. The reservoir also conceals the EPDM from UV exposure, preventing UV degradation.

Application Use: Medium-duty - This low-profile metal roof bracket can be attached directly to the sheeting, accommodating ancillary attachment anywhere along the corrugation.

Application Use: Heavy-duty - The bracket can be fixed into the underlying substrate for additional support without crushing the corrugation.

LEARN MORE ABOUT CORRUBRACKET™ 100T

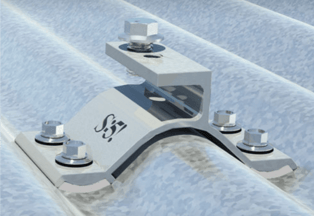

CorruBracket™ 500T

CorruBracket™ 500T

The CorruBracket 500T is the perfect attachment solution for 16–18 mm corrugated roofing. Designed specifically for the Australian, Asian and African markets, this bracket prevents penetration from occurring in the profile valley.

Application Use: Medium-duty - This metal roof bracket can be attached directly to the sheeting, accommodating ancillary attachment anywhere along the corrugation.

Application Use: Heavy-duty - The bracket can be fixed into the underlying substrate for additional support without crushing the corrugation.

LEARN MORE ABOUT CORRUBRACKET™ 500T

WHO INVENTED THE CORRUGATED PANEL?:

Henry Robinson Palmer patented corrugated iron in 1829. Palmer was an architect and engineer to the London Dock Company. Corrugated panels became specifically useful when building prefabricated structures. Additionally, the material was touted for its corrosion-resistance and strength. Around the 1890s, wrought iron was replaced with steel. Today, corrugation is made through a process called roll forming. Sheet metal is rolled through dies that form the desired corrugation in the metal.

The most common corrugated materials include coated carbon steel, stainless steel, aluminum, and copper. Even non-metal materials are corrugated as well. Plastic and fiberglass are corrugated and then used as translucent ceilings or roof lights.

Why are S-5! Products the Most Trusted and Engineered

Products on the Market?

Metal Roofing from (A) Aluminum to (Z) Zinc– MCA