Part Two -

Welcome to part two of our three-part series on 3 Tips for Mounting Anything to Your Exposed-Fastened Metal Roof. Our goal is to help you preserve your metal roof’s service life as you attach solar panels, snow guards, HVAC equipment or other accessories.

We hope you gained some new insights from our first blog in this series on the importance of materials compatibility.

In the near future, we’ll round out these valuable tips with an explanation of how load testing the brackets of your rooftop-mounted ancillaries is key to protecting your exposed-fastened (EF) metal roof.

Today, we are taking a deep dive into another vital topic to preserve your roof’s integrity: the world of proper sealants.

Tip #2: When Should You Use EPDM and Butyl Sealants?

EPDM and butyl sealants are two of the most effective weatherproofing products in the metal roofing industry with decades of proven success. Because mounting accessories involves penetrating through your EF roof, these exceptional sealants are critical to prevent roof leaks not only initially, but over the life of your roof. Let’s look at how you can make the most of these sealants.

How Can You Prevent Leakage and Water Intrusion?

Holes in your roof must be sealed, but externally applied caulking and sealants eventually dry out and crack, causing leakage and corrosion.

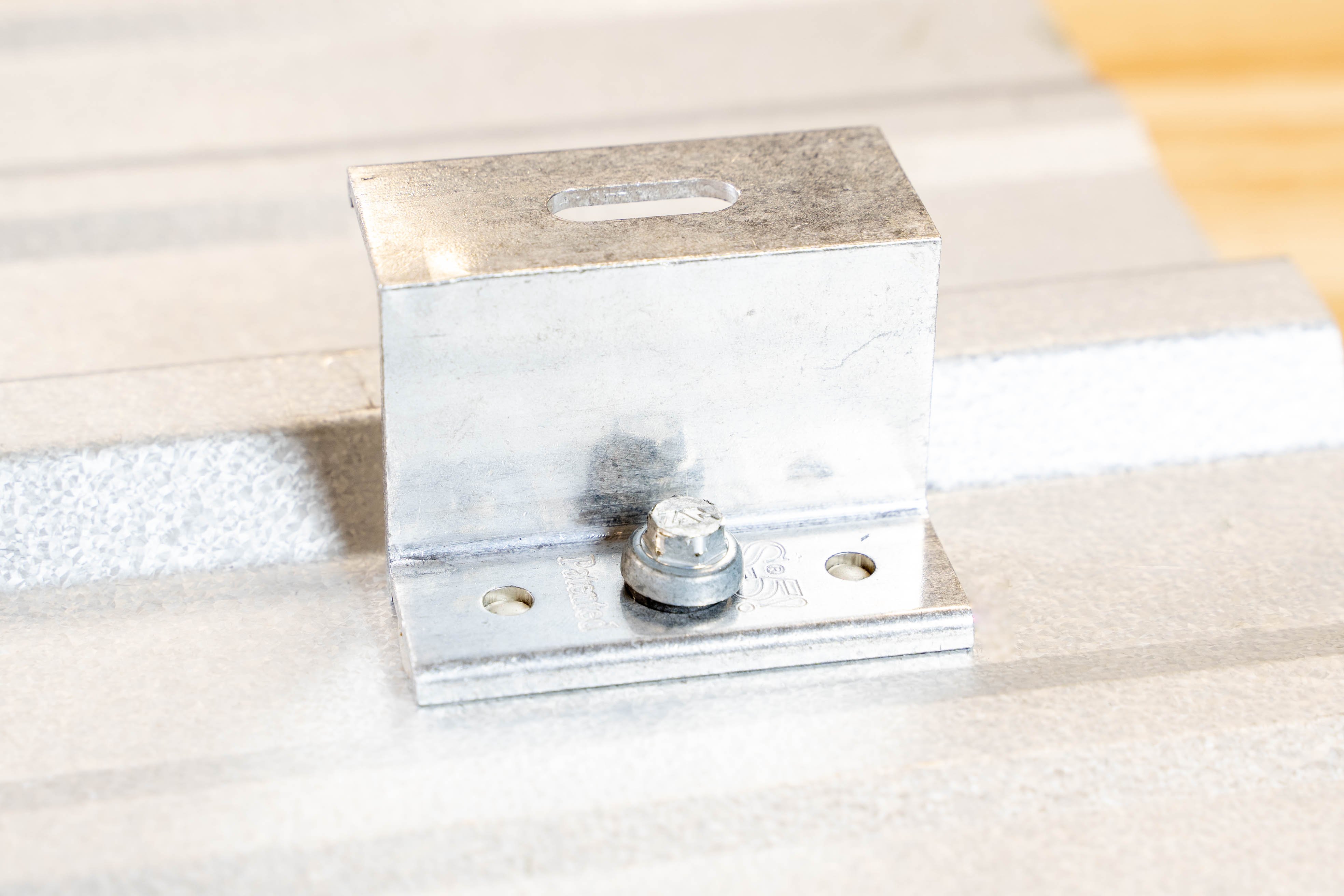

Poor and messy externally applied caulking and sealant on an exposed-fastened metal roof

Factory-applied sealants give you top performance.

Fasteners with factory-applied EPDM and butyl sealants give you dependable weatherproofing without messy, unstable in-field applications. Factory-applied sealants also eliminate the cost and risk of choosing less-effective products in the local marketplace.

What Makes EPDM and Butyl Sealants So Effective?

Here’s a quick rundown of their features:

What Is EPDM Sealant?

EPDM (ethylene propylene diene monomer) is a smooth, semi-hard, synthetic rubber. You can count on EPDM for high-tensile strength, flexibility, long lifespan, reliability in hot and cold climates and moisture resistance. EPDM is so waterproof, it’s even used as pond liners. A preferred roofing material for more than 40 years, EPDM is a favorite product of the commercial roofing industry.

What Is Butyl Tape Sealant?

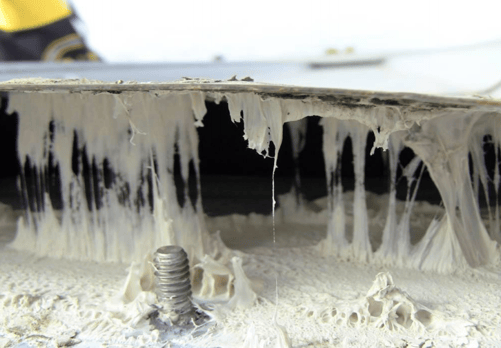

Butyl tape sealant (a copolymer of isobutylene with isoprene) is an airtight, watertight adherent rubber establishing an impervious moisture barrier. Isobutylene copolymers have been used in the U.S. low-slope metal roofing industry for more than 50 years thanks to their reputation for excellent performance. Uncured and sticky, butyl remains flexible even in extreme temperatures. One study shows butyl tape is still elastic and pliable after 33 years, and it’s estimated to last 60+ years.

Excellent elasticity demonstrated by the butyl sealant on a Denver metal roof after 33 years in service.

Excellent elasticity demonstrated by the butyl sealant on a Denver metal roof after 33 years in service.

How Can You Extend the Materials’ Lifespan?

As is true for almost anything, specific formulations of these sealant types differ from one manufacturer to another. Their individual formulations are proprietary and create their own “secret sauce.” In other words, they don’t all necessarily perform the same. This makes it imperative to source from a vendor who has a long history of success.

Beyond choosing a vendor with known integrity, the life of both EPDM and butyl tape can be extended in two ways to ensure their best performance over time:

- Don’t use any sealant as a surface-applied fix on a roof. Sealant chemistry is complicated. If sealants aren’t properly protected, multiple factors can break down their chemical bonds. Surface applications are subject to degradation from UV, ozone, mechanical abrasion, dirt and other contamination. Application as a gasket material will help protect sealants from these threats. But even when applied as a gasket material, the best sealants can still have vulnerabilities. Look for attachments where the sealant is concealed from exposure and even protected at its edges if possible.

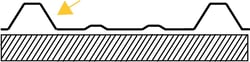

- Avoid over-compression. Tighter is not better in this case. When you drive in the screw, seat it, but don’t over-torque it. Otherwise, you could thin and displace the gasket material, reducing its life and effectiveness. The best practice is to utilize a part design featuring a built-in-like “reservoir” to encapsulate the material and help prevent over-compression.

|

|

|

Over-Compressed Screw |

Properly Seated Screw |

Where Is the Best Place to Use EPDM vs. Butyl When Mounting Your Attachments?

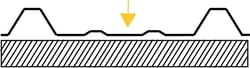

Is your roof in the U.S. or abroad? Interestingly, geographic locations affect mounting preferences. We call it “roof culture,” and it varies. Attaching into the flat of the panel (the low valley of your corrugation or flat area between trapezoidal ribs) is commonplace in the U.S. thanks to time-tested waterproofing sealants. For installers in other roof cultures, the penetration is in the higher point of the profile, away from the drainage plane (into the rib). These differentiators are sometimes called “bottom-fix” and “top-fix.”

|

EPDM is a top choice when attaching in the high (into the rib). |

Because EPDM is semi-hard (like gasket material), it needs to attach to a flat, even surface to create a watertight connection. The smooth rib of your EF roof profile is a perfect match for EPDM.

Image of a roof profile with the bracket attached on the rib.

|

When mounting in the low (valley), butyl sealant is ideal. |

Butyl’s flexible nature allows it to conform to the irregular surfaces (minor ribs and striations) in the panel valley. By using butyl tape, the sticky sealant retains its shape for a mess-free application. When mounting in the low, use only products designed to attach through the roof sheet into the structure or deck – never to the sheet only – in order to ensure stability, weathertightness and roof protection.

Image of a roof profile with the bracket attached in the valley.

Need help finding the right bracket for your upcoming solar mounting project?

Tell us about your project and we'll guide you to the best fit product for your specific roof panel.

Whether you mount in the high or the low, look for attachments with more than one seal at penetration points. S-5!’s attachments offer a double seal in the high of the rib and a triple seal in the low to eliminate the possibility of leakage and give your roof lifetime service without messy field-applied sealants. Get the details of how we do it.

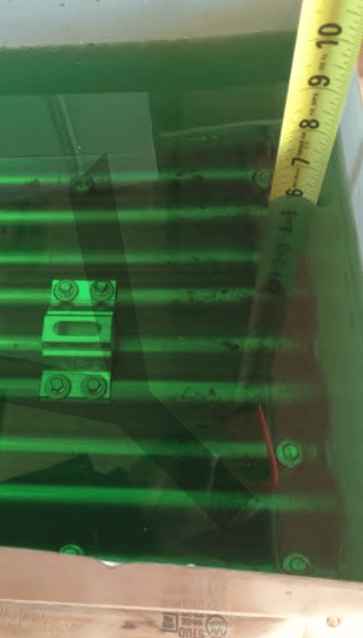

Image demonstrating how butyl sealant swells into the threads of metal-to-metal fasteners.

|

|

|

| Metal-to-metal fasteners | Metal-to-metal fastener partially threaded and removed (note swelling of butyl sealant in threads) | Fully seated metal-to-metal fastener |

How Does S-5! Test for Weather Integrity?

We prove our products’ weathertight claims through top industry-respected tests: ASTM E-2140 and ASTM E-1646.

- ASTM E-1646 simulates wind-driven rain. Fifteen gallons of water per minute are sprayed directly at the joint or point of penetration. Vacuum pressure beneath the sample attempts to pull the water through it while leakage is monitored.

S-5! products pass these ASTM tests to ensure watertight performance.

S-5! products pass these ASTM tests to ensure watertight performance.

|

|

ASTM water testing - bracket submerged 6" to fasteners. (Product shown: S-5! CorruBracket™) |

Ideas to Hold Onto

EPDM and butyl are top sealants on the market, and we’ve looked at several ways you can make the most of their great qualities:

- Use products with factory-applied sealants.

- Select parts designed to protect sealants from over-compression, UV and environmental contamination.

- Use EPDM when attaching into the high of the rib and butyl in the low.

- Look for product designs that use more than one seal.

- Use only products tested according to strict ASTM protocols with track records of proven performance in the field.

Now when mounting attachments on your EF metal roof, you know how to leverage EPDM and butyl sealants to avoid roof leaks and protect the life of your roof.

Stay tuned for the final blog in our three-part series 3 Tips for Mounting Anything to Your Exposed-Fastened Metal Roof, which will cover load testing. And if you missed our first tip on materials compatibility, be sure to check it out.