Part One -

Are you mounting solar panels, snow guards, HVAC equipment or other accessories to your exposed-fastened (EF) metal roof?

If so, we’ve put together a three-part series on our top tips for successful installation to preserve your roof’s service life.

Over the course of the next three blog installments, we’ll cover:

- The importance of materials’ compatibility between the mounting attachments and your metal roof.

- The right time and place for you to use EPDM and butyl sealants.

- Why load testing is key to protecting your metal roof.

This series will help you understand how a range of factors work together to prevent leaks and other damage from occurring. It’s important to install attachments without causing harm to your roof, and our goal is to help you make the best choices to protect your EF roof.

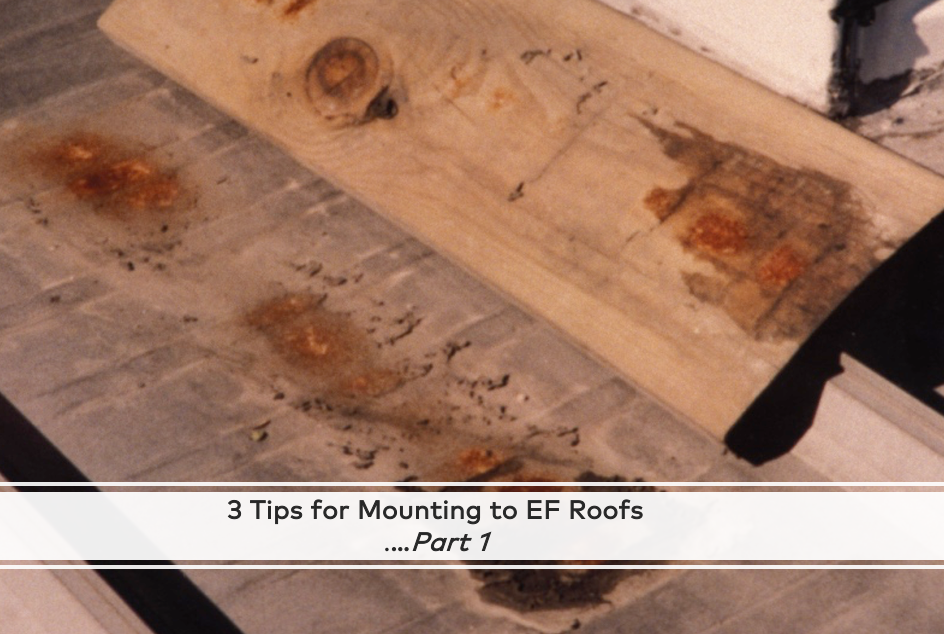

(Image above: This is an example of poor weather-proofing on an exposed-fastened metal roof with screws and sealant. This can lead to trapped moisture and eventual corrosion.)

Let’s get started.

Tip #1: Are Your Mounting Attachments and Exposed-Fastened Metal Roof Compatible?

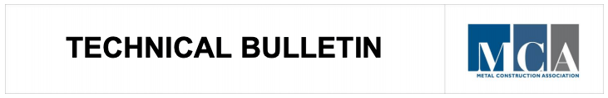

Begin with a fresh assessment of your roof. Your current metal panel profile and substrate may look just like others, but beware, there may be subtle but important differences in:

Differences to consider in panel profiles and substrate

Differences to consider in panel profiles and substrate

Is Your Roof Compatible With the Attachments and the Hardware?

Did you know the material type of your EF roof can greatly affect the long-term success of your project? It matters more than you might think. When materials aren’t galvanically compatible, you could compromise the system.

What type of metal is your roof? Aluminum? Galvanized steel (coated with zinc)? Galvalume® (steel coated with an aluminum-zinc alloy)? You need to know what material your roof is made of to ensure your attachments are manufactured with compatible metals. Otherwise, when certain metals come in contact with each other, a corrosive reaction can take place. Learn all about metallic coatings here.

Chemical Reactions Between Metals

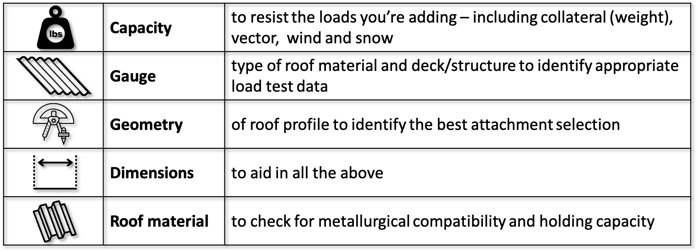

(Image to the left: A common mistake is using graphite pencil to mark aluminum, aluminized or Galvalume®-coated steel. Graphite has a severe corrosive effect on aluminum and will cause etching of the surface.)

Here are two metal terms every installer should know: Anodic metals (these metals release electrons) and cathodic metals (these metals attract electrons). Aluminum, zinc and coated steel are examples of anodic metals. On the other end of the spectrum, lead, copper and Series 300 stainless steel are cathodic metals.

In some cases, if metals from those two opposing categories aren’t separated, you’re at risk of corrosion and potential full-system failure. But the oxide layers created by the parent metal also make a difference - some oxides act as insulators while others do not.

Learn More About Metallurgical Compatibility

|

Check out the table on Page 3 of this compatibility guide to see which metals and coatings should remain separate. |

Reactions From Surprising Sources

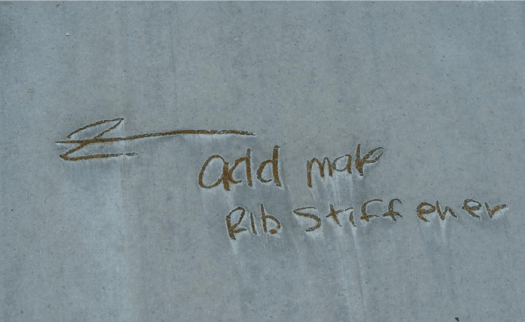

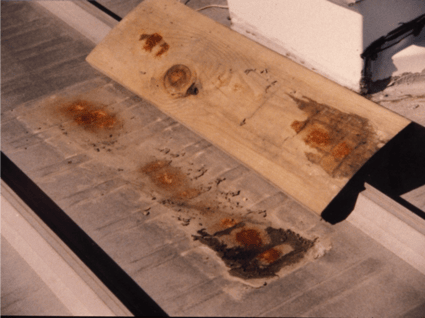

Acids and alkalis also come into play. Treated lumber (which often contains copper azole or alkaline copper quaternary copper salts) can release cathodic ions and chemicals onto your roof.

Stucco, masonry blocks and concrete (often used as ballast) can leech alkalis onto aluminum or Galvalume® roofing, inducing corrosion.

It’s the same for the brackets you use to attach rooftop accessories – the bracket materials need to be compatible with your EF metal roof to prevent corrosive interactions.

(Image to the left: Using timber to mount on a metal roof can cause corrosion.)

avings on a me

We know it can be a complex topic.

Get a detailed explanation of how dissimilar metals can cause corrosion by visiting the link above to the Metal Construction Association's Technical Bulletin on "Dissimilar Metal Corrosion in Roofing Installations."

|

Not sure if interactions with your roof material can occur? Reach out and ask! |

Where Will Your Attachment Points Be?

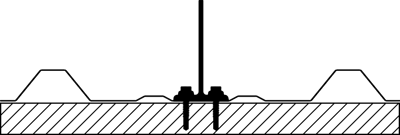

EF metal roofing can be installed over open structural framing or a deck. Will you anchor to the profile rib itself? If not, and you’re going through the panel valley and into the substrate beneath (steel purlins, wood purlins, plywood, steel decking or OSB), these factors add another layer to your decision-making process. You need to use the right hardware.

Exposed-fastened bracket installed into decking on purlin bearing rib (PBR) panel

.png?width=357&name=CB%20on%20roof%20with%20fasteners_02%20(1).png)

Exposed-fastened bracket installed into decking on corrugated roofing profile

Exposed-fastened bracket installed into sheeting on corrugated roofing profile

Are You Using the Right Screw for Your Job?

All screws are not created equal, and it’s important you choose the correct fastener for the job. Those generic screws at your local DIY store (or laying around in your toolbox from a prior job) may not be suitable for the project at hand.

When attaching through metal into metal, you definitely want to use a metal-to-metal drill screw. If you’re attaching through a wood purlin, use a piercing point (non-drilling) metal-to-wood fastener.

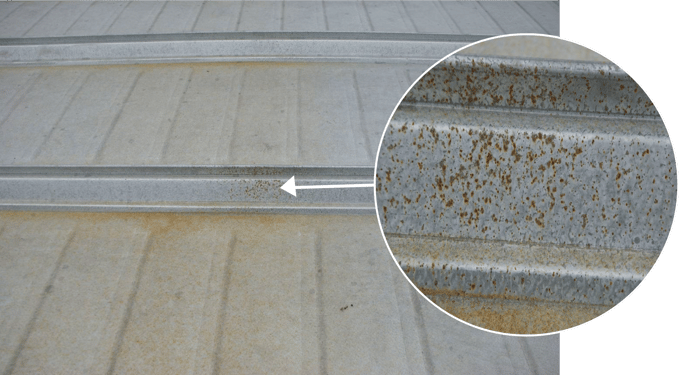

Self-drilling screws can leave metal shavings (swarf) on the roof, resulting in unsightly and potentially harmful rust stains. Self-piercing screws avoid swarf, and they’re necessary when you’re attaching to sheet-only panels.

Swarf shavings caused rust on a metal roof

Exposed fasteners are exactly that – exposed:

- Exposed to moisture

- Exposed to extreme temperatures and ultraviolet rays

- Exposed to wind and debris

Rain, intense sun, and wind are a few of the weather-related forces that can negatively impact fasteners

Your exposed-fastened roof fasteners are vulnerable to many environmental threats. Screw heads are subject to eventual corrosion unless they’re stainless steel or aluminum-zinc. Gaskets can be subject to UV degradation. Get the highest quality, weathertight hardware to ensure long-life protection.

Preserve Your Roof’s Service Life

The lifespan of your brackets and fasteners should match the lifespan of your roof. If your bracket fails earlier than your roof or the equipment you’re attaching, the failing bracket could compromise the system’s strength. Look for brackets and screws with documented load-to-failure strength and weather seals specifically designed and engineered to last the life of your exposed-fastened roof.

Ideas to Hold Onto

We know you want to protect your metal roof and the investment you’ve made, so consider the following items before you mount anything on your EF roof:

- Assess your roof’s unique features.

- Check for materials’ compatibility and possible electrochemical reactions between your EF metal roof and attachments.

- Use the correct fasteners with high-quality weather resistance.

- Make sure your brackets will last as long as your roof.

This blog is the first part of our series on 3 Tips for Mounting Anything to Your Exposed-Fastened Metal Roof. We’ve got more great suggestions for you! Stay tuned for our second tip where we cover need-to-know details on sealants.