Metal roofs are a smart investment because they can last over 60 years with minimal upkeep. They are sturdy and perform well in harsh weather conditions such as fire, wind, snow and hail. Metal roofs are also eco-friendly, as they can be recycled when their lifespan comes to an end. This makes them a durable, cost-effective and sustainable choice for homeowners.

While metal roofing has many benefits, some common myths still surround it. Most metal roofing is coated steel. One of the most frequent misconceptions is that steel roofs rust. True — when you are looking at a steel roof with an inferior coating or one that is 50, 60 or 80 years old! We're here to set the record straight on all the rest! In this blog, we’ll explain that when selected and installed correctly in today’s reality, metal roofs are inherently resistant to rust.

Rust Explained: What It Is and Why It’s a Problem

Rust is a type of corrosion that occurs when some metals, such as iron or steel, react with water and oxygen in the air. When these elements come into contact with most metals, they trigger a chemical reaction that produces an oxide layer that protects the base metal from further corrosion. Steel is an exception to this rule, however, and produces a substance called iron oxide. This substance is what we recognize as the reddish-brown flakes or spots commonly referred to as rust. And it does not protect the base steel.

Rust can be a serious issue on steel roofs if the wrong products are used and proper installation processes are not followed. In this example, the roof is doing quite well, but the ancillary curb is fabricated from material having an inferior coating to the roof.

Rust gradually weakens steel over time, causing it to break down or suffer damage. Steel is most prone to rust because of its high iron content. Rusted steel can weaken the adjacent metal and lead to further damage.

Metal Roofs Don’t Rust Like You Think

Scary, right? But don’t worry — when metal panels are made and installed properly, rust isn’t a problem on your home’s roof. Why? Let’s dive in:

- Coatings

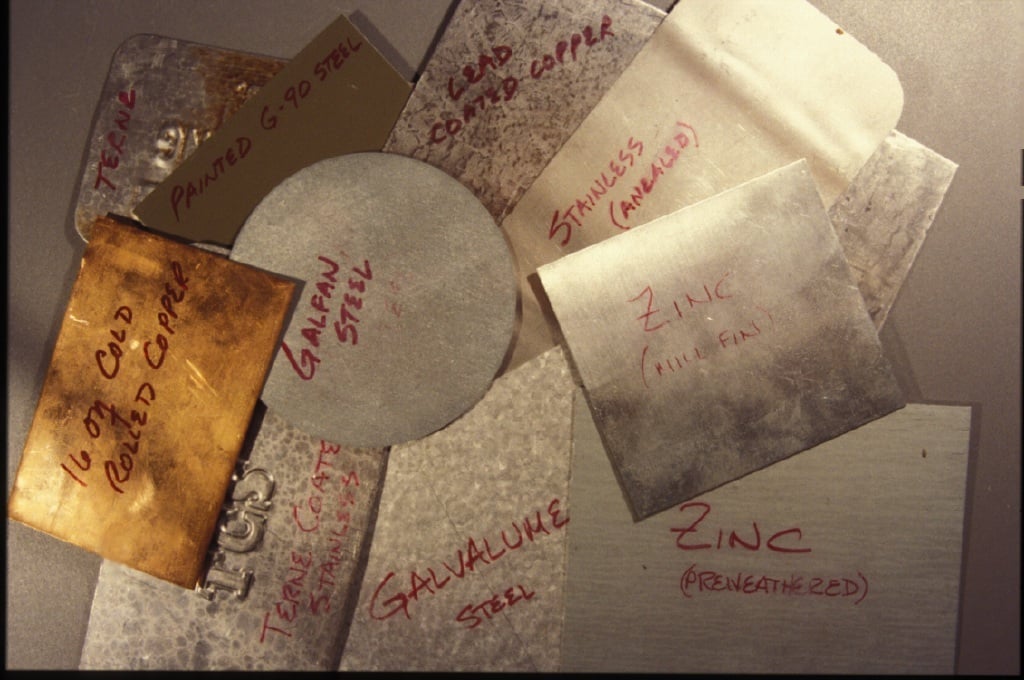

The top layer of your roof consists of panels and trim, which are directly exposed to the weather and the environment. Uncoated steel rusts easily, but this can be prevented or slowed by applying protective coatings like aluminum, zinc or a combination of both called Galvalume®. Galvalume is a coating for steel that combines the corrosion resistance of aluminized (aluminum-coated) steel with the benefits of galvanized (zinc-coated) steel. It was co-invented in the late 1960s by Angelo Borzillo and Jim Horton of Bethlehem Steel, and its composition includes 55% aluminum, 43.4% zinc, and 1.6% silicon (by weight). The silicon additive helps with adhesion during fabrication.

This metallic coating is applied via a hot-dip process at about 1200 degrees Fahrenheit, creating an inter-metallic layer that metallurgically bonds the coating to the base steel. The coating isolates the base steel from exposure to air and moisture, preventing oxidation of the steel (red rust). It should be noted that painting of a steel substrate is not done instead of metallic coating, but in addition to it. The corrosion protection is the job of the metallic coating, not the paint.

Steel is provided with a protective coating, such as Galvalume, that shields it from corrosion.

- Proper Installation

Rust can form quickly when excess water remains on a coated steel surface for a long period of time or when moisture becomes trapped against its surface. That’s why steel roofing materials need to be appropriately stored and given adequate airflow before and following installation.

Rooftop mounting solutions that allow the free flow of rainwater can reduce the risk of rust.

It’s essential for different skilled trades to carefully coordinate when installing metal roofing and rooftop accessories, such as HVAC, to reduce the risk of rust. Poor planning during installation can trap moisture in certain areas, leading to rust and corrosion over time.

- Care and Maintenance

Regular inspections of a metal roof are crucial for maintaining its integrity and durability, and for reducing the risk of rust. By performing routine visual inspections, homeowners can detect early signs of moisture buildup, trapped debris or damage that could lead to corrosion over time. Addressing these issues promptly ensures that protective coatings remain effective and that components like flashing and vents function properly.

Additionally, inspecting for any potential sources of galvanic corrosion, such as incompatible metals, helps prevent rust before it starts. This proactive approach not only extends the roof's lifespan but also saves homeowners money in the long run by avoiding costly repairs and premature replacements.

Your Attachments Matter

Roof panel manufacturers should provide clear guidance on the appropriate type of attachments and fasteners for their products to minimize the occurrence of rust. Fasteners should be made of the same material (or a compatible one) as the roof or wall systems whenever possible to avoid dissimilar metal corrosion. If not, the fastener should have at least the same level of corrosion resistance as the material being fastened. For example, using galvanized steel fasteners with aluminum wall cladding systems is not recommended.

Swarf refers to the metal shavings and debris produced during machining processes, such as drilling and cutting. On exposed-fastened roofs, swarf results from the use of self-drilling screws when attaching brackets to the panel. These screws remove (uncoated) material from the metal surface and deposit it on the roof panel, which can lead to corrosion and rust stains when drilling their holes. However, utilizing brackets with self-piercing screws can greatly reduce the occurrence of swarf. These screws are designed to penetrate the panel without removing excess metal, thus minimizing debris and helping to maintain the integrity and aesthetic of the roofing material.

Sourcing the appropriate attachment and fastener for your metal roof is critical to reducing the risk of rust.

Other corrosive processes may pose a concern, even in situations where metals do not appear to be present. For instance, using fire-retardant or preservative-treated lumber should be avoided with all metal roofing materials, except for copper. The chemicals used in treated wood often contain high levels of copper salts and other corrosive elements. When these materials become wet, the dissimilar metal corrosives dissolve and start chemically attacking the metal roofing material.

This same corrosive reaction occurs when graphite pencils are used to mark coated steel or aluminum roofing material. The graphite quickly corrodes the metal, and within a short period, rust appears. It is recommended that a felt marker be used when marking metal roof panels.

Graphite is corrosive to most coated steel, including Galvalume, and can lead to rust over time.

Ideas To Hold on To

So, there you have it — steel roofs do not rust like many people believe. Metal roofs stand out as a reliable and durable option that can enhance the longevity and sustainability of your home. With the right coatings, proper installation and regular inspections, homeowners can enjoy the numerous benefits of steel roofing without the worry of rust. Embrace the advantages of metal roofs and enjoy peace of mind for decades to come!

If you have any questions or would like to learn more about metal roofing, browse our other blogs and enroll in S-5-University™ today.